BLOG

-

Extrusionsformen verstehen: Das Rückgrat der modernen Fertigung

Einleitung Das Extrusionsformen ist ein zentraler Prozess in der modernen Fertigung und ermöglicht die Herstellung kontinuierlicher Formen und Profile mit Präzision und Effizienz.Dieser Blog befasst sich mit den Feinheiten von Extrusionsformen und untersucht ihre Geschichte, Anwendung ...Mehr lesen -

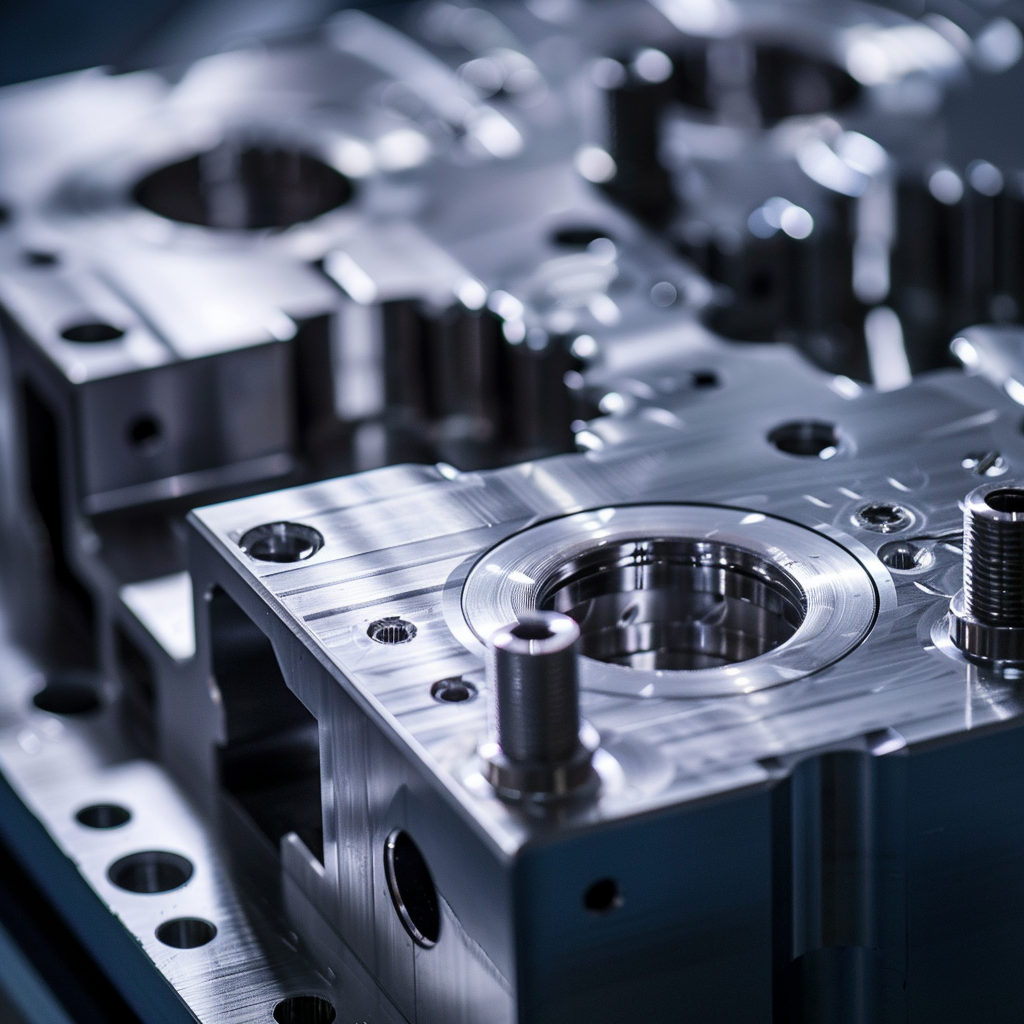

Die Bedeutung und Wartung von Spritzgussformen in der Fertigung

Spritzgussformen sind im Herstellungsprozess von entscheidender Bedeutung, insbesondere für die Herstellung präziser Kunststoffteile.Die Haltbarkeit und Lebensdauer dieser Formen wirken sich direkt auf die Produktionseffizienz und -kosten aus.Mit einer gut gewarteten Form können Hunderttausende Teile hergestellt werden, was...Mehr lesen -

Der Unterschied zwischen Materialgravur und Tampondruck

Die Spezifikationen und Informationen aktueller Produkte sind zu einem unverzichtbaren Bestandteil geworden.Die meisten Hersteller gravieren die Informationen durch Siebdruck, Tampondruck oder Metallgravur auf die Produkte.Verstehen Sie jedoch wirklich die Vorteile und d...Mehr lesen -

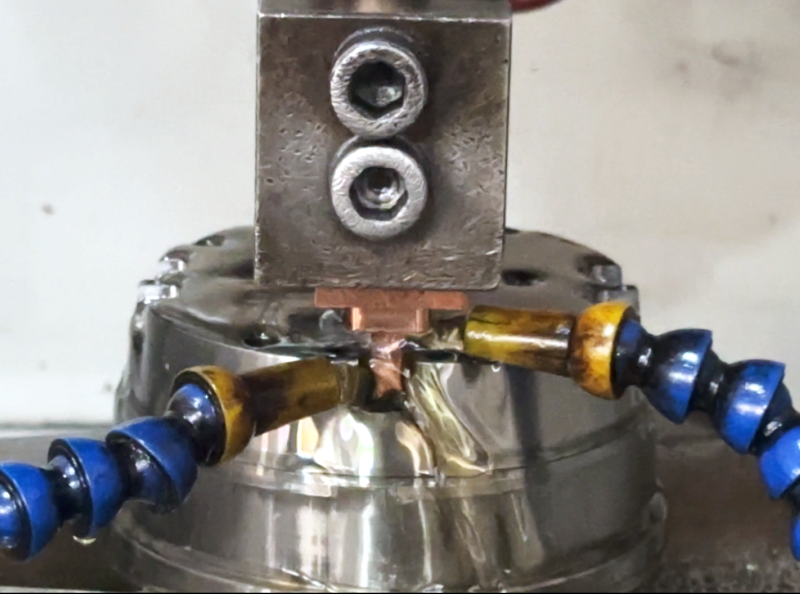

Elektrofunkenbehandlung in der Formenbearbeitung

Heute besprechen wir die Anwendung der Elektrofunkenabscheidung in Metalllegierungen. Gleichzeitig konzentrieren wir uns auf diese Technologie, wie die Form in Spritzgusswerkzeugen und Gussformen modifiziert werden kann.Was ist Elektrofunkenabscheidung?...Mehr lesen -

So wählen Sie zwischen Spritzguss und CNC-Bearbeitung

CNC und Spritzguss sind die beiden beliebtesten Fertigungsverfahren, die in beiden Bereichen qualitativ hochwertige Produkte oder Teile herstellen können und ihre eigenen Vor- und Nachteile haben.Daher kann es eine Herausforderung sein, den besten Weg für ein Projekt auszuwählen.Aber als Profi...Mehr lesen -

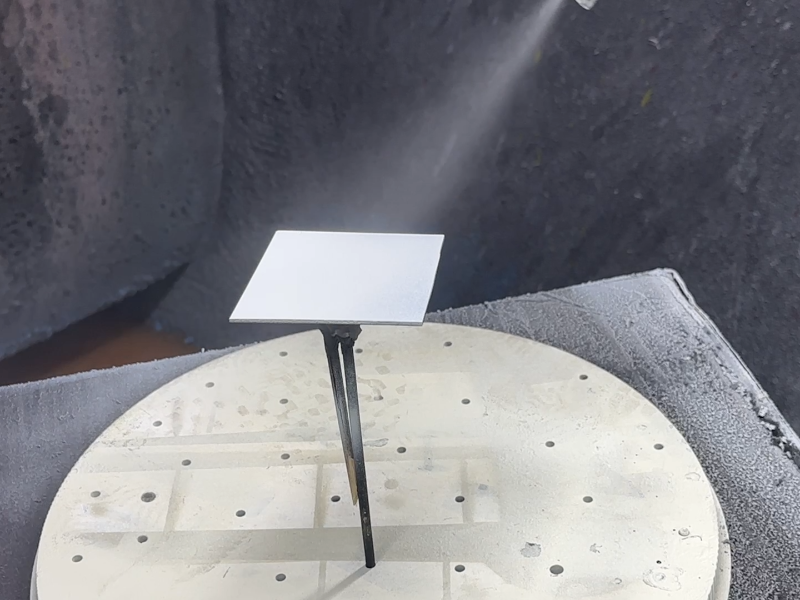

Wie man Gesundheits-, Sicherheits- und saubere Medizinprodukte herstellt

Bei medizinischen Geräten sind Sauberkeit und Sicherheit von entscheidender Bedeutung.Alle medizinischen Geräte, ob Einweg-, implantierbare oder wiederverwendbare, müssen während des Herstellungsprozesses gereinigt werden, um Öl, Fett, Fingerabdrücke und andere Herstellungsverunreinigungen zu entfernen.Wiederverwendbares Pro...Mehr lesen -

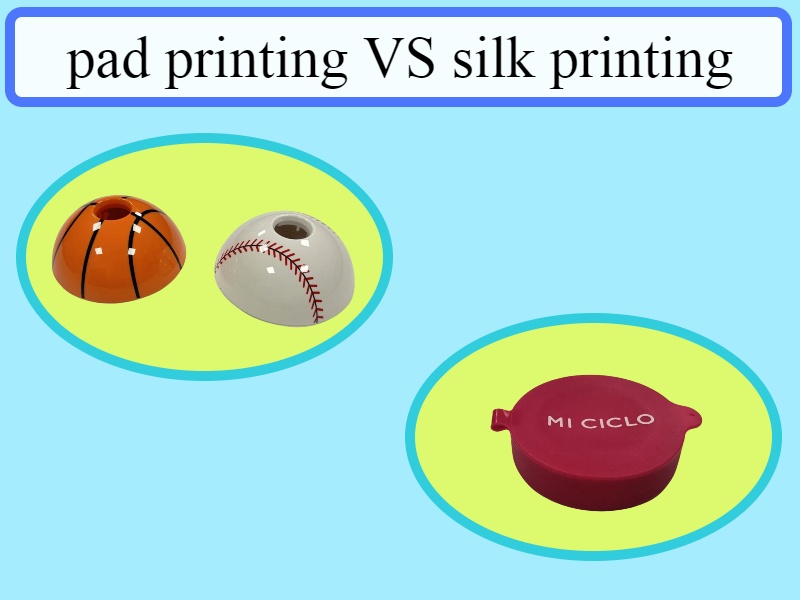

Den Unterschied zwischen Tampondruck und Siebdruck verstehen

Tampondruck und Siebdruck sind zwei unterschiedliche Druckverfahren, die auf einer Vielzahl von Produkten und auf einer Vielzahl unterschiedlicher Materialien eingesetzt werden.Der Siebdruck wird auf Textilien, Glas, Metall, Papier und Kunststoff eingesetzt.Es kann auf Luftballons, Aufklebern, Bekleidung, medizinischen ... verwendet werden.Mehr lesen -

Seidendruck in Mode- und Heimdekorationsprodukten

Was ist Seidendruck?Beim Siebdruck wird Tinte durch ein Schablonensieb gepresst, um ein gedrucktes Design zu erstellen.Es handelt sich um eine umfassende Technologie, die in verschiedenen Branchen weit verbreitet ist.Der Prozess wird manchmal Siebdruck oder Siebdruck genannt, aber diese Namen sind wesentlich...Mehr lesen -

Der Leitfaden zu Nachbearbeitungsmethoden für Spritzgussformen

Durch die Nachbearbeitung werden die Eigenschaften von Kunststoffspritzgussteilen verbessert und für den vorgesehenen Endgebrauch vorbereitet.Dieser Schritt umfasst Korrekturmaßnahmen zur Beseitigung von Oberflächenfehlern und eine Nachbearbeitung zu dekorativen und funktionalen Zwecken.Im RuiCheng, p...Mehr lesen -

Was ist Tampondruck?

Der Tampondruck, auch Tampographie oder Tampondruck genannt, ist eine vielseitige indirekte Offsetdrucktechnik, bei der mithilfe eines Silikontampons zweidimensionale Bilder von einer lasergravierten Druckplatte auf dreidimensionale Objekte übertragen werden.Dieser Prozess ermöglicht das Drucken von...Mehr lesen -

Metall oder Kunststoff: Was sind die Unterschiede?

Bei der Herstellung eines Produkts kann die Wahl zwischen Kunststoff und Metall schwierig sein.Beide Materialien haben ihre einzigartigen Vorteile, weisen aber auch einige überraschende Gemeinsamkeiten auf.Beispielsweise können sowohl Kunststoff als auch Metall Hitzebeständigkeit und Festigkeit bieten, w...Mehr lesen -

Etwas, das Sie über das TPU-Spritzgießen wissen müssen

TPU-InjektionEs gibt verschiedene Methoden des TPU-Formprozesses: Spritzgießen, Blasformen, Formpressen, Extrusionsformen usw., wobei Spritzgießen am häufigsten vorkommt.Die Funktion des Spritzgießens besteht darin, TPU in die erforderlichen Teile zu verarbeiten, was unterteilt ist...Mehr lesen